As we dive into finding solutions for fall hazards, let’s get a quick refresher from our fall hazard risk assessment blog.

Until you know where your risks are, it is difficult to develop an effective strategy to reduce risk. Be sure to evaluate the three main types of hazards:

- Means of Access Hazards – ramps, stairways, and more

- Location Hazards – roof hatches, scaffolding, and more

- Hidden Hazards – skylights, non-certified horizontal lifelines, and more

Eliminating and Controlling Fall Hazards

Organizations with workers exposed to elevated work surfaces must balance worker safety and organizational budgets. Despite common misconceptions, these don’t have to clash with each other.

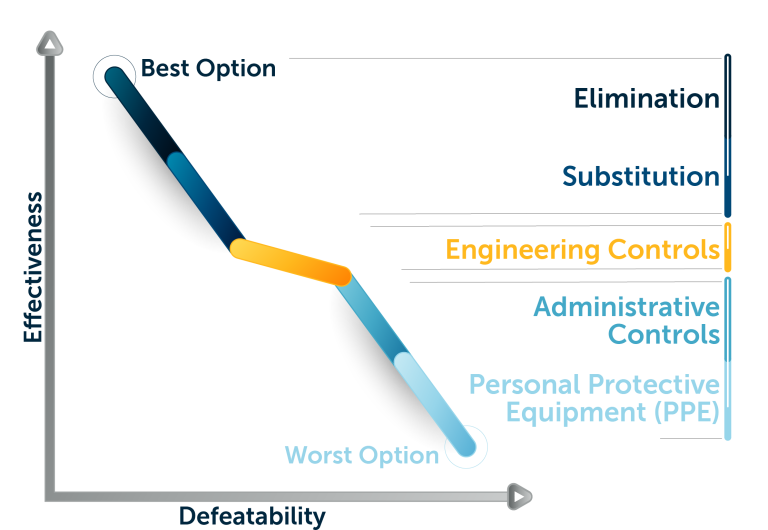

When identifying and selecting fall hazard abatement options, consider how effective the systems will be, how easily they can fail, and up front vs recurring costs. The fall protection Hierarchy of Controls (HoC) is a method used to weigh these factors. When prioritizing abatement options, consider elimination and substitution, engineering controls, and administrative controls in that order. Let’s dive into each below:

Elimination

Eliminating a fall hazard should always be considered first, as it is the most effective and least defeatable option for abating fall hazards. This removes fall hazards from the start.

- Pros: highest level of safety; no recurring costs

- Cons: high up-front implementation costs

Substitution

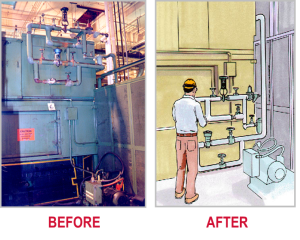

Substituting a fall hazard with an alternative is the next most effective solution. Think of a solution that would allow a worker to stay on the ground for the task versus having them work at height, such as ground level mechanical equipment in lieu of roof-mounted equipment.

- Pros: highly effective option with no recurring costs

- Cons: high up-front implementation costs

Engineering Controls

The third control option to consider is using engineering controls. These are also known as passive systems, which require no action by the worker. A guardrail is a common example.

- Pros: still highly effective with minimal recurring costs

- Cons: high up-front implementation costs; can carry aesthetic concerns

Administrative Controls

Administrative controls, such warning lines or work procedures, are the first level of active fall protection and require a great deal of cooperation from workers. Because you are reliant on worker behavior, you are sliding further down the scale of effectiveness. It’s certainly still better than nothing.

- Pros: low up-front implementation costs

- Cons: higher coordination and training efforts, higher recurring costs, and higher likelihood of failure

Personal Protective Equipment (PPE)-Based Fall Protection Systems

The last option to consider is the use of personal protective equipment-based systems (PPE). PPE-based systems are heavy on inspection, maintenance, and training. Again, PPE is better than nothing, but it should be a last resort when other solutions are not possible.

- Pros: it’s better than nothing if it’s your only option

- Cons: low-effectiveness, dependent on worker behavior, can easily fail, implementation and recurring costs

While PPE-based solutions are the least desirable options, some circumstances lend to their use. To help you track your active fall protection systems, HERE is a free tool you can use. Look for the Active Systems Management Tool on our Resources page.

Wrapping Up

If you ever have any questions on fall hazards or other fall protection issues, please reach out to us HERE. Thanks for reading!