As fall fatalities continue to rise nationwide , you’ve decided to prioritize this aspect of safety and fall protection within your organization. This is the year you take a stand and do everything you can to better protect your workers at heights. But where do you start?

Greg Lees

The Challenge of Fall Protection

The U.S. Bureau of Labor Statistics reported that fall, slip, and trip fatalities in the United States rose from 850 in 2021 to 865 in 2022. The continued rise in fatalities has multiple causes, but can be partially attributed to a lack of specific processes, safety-minded overall culture and individual mindset. Even with a stronger focus on preventing falls, it will take time for the overall number of fall fatalities to decrease because it simply takes time for the risk assessments, hazard control, training, and other fall protection initiatives to be implemented and take hold.

Fall protection is complex. There are numerous regulations, standards, equipment options, training sources and priorities. Plus, fall protection presents two conflicting realities:

- Significant fall incidents don’t happen often.

- When they do occur, they’re catastrophic and costly.

Unfortunately, the rarity of accidents can lull both management and workers into a false sense of security. Managing the major risks presented by falls is a smart and ethical business investment—in addition to a legal requirement.

This is also a reason the Occupational Safety and Health Administration (OSHA) created the National Emphasis Program. Its goal is to get ahead of fall fatalities and injuries.

Defining Your Fall Protection Program Goals and Objectives

Setting goals and objectives for your fall protection program is a great place to start. You can begin by asking questions regarding various aspects of your program to help you define your goals and objectives.

Survey Questions

- What do you think is your greatest risk?

- Have you completed a Hazard Assessment per 29 CFR 1910.132(d)?

- What did you find?

- How did you look for walking working surface integrity, different hazard types, systems criteria, etc.

- Are you compliant?

- How would your leadership react if they had this information?

- How could you better manage working at elevated heights with this information?

Competent Person Questions

- What is your training like? Trainer qualifications, length, topics, hands on vs academic, harness fitting, suspension simulation, customized to your hazards, etc.

- How many are trained? Who? Which shifts?

- Do you cover all the manufacturers and products your workers are provided during training?

- If you are manufacturer trained, how did it properly cover all relevant topics beyond their equipment? Products are typically the focus of manufacturers’ training as it is what they know best. Some of the more important programmatic items might not be covered as they should be.

System Design Questions

- Is the designer a Qualified Person?

- Do you have the calculations?

- Do you have a copy of the drawings?

- How does the worker in the field know any parameters or restrictions for proper use of the system?

- Did the designer prepare use and rescue procedures?

By asking these questions, you can discover gaps in key areas that need to be addressed in your fall protection program. Next, we’ll address where you need to look to determine how to be compliant and go above and beyond to protect your workers.

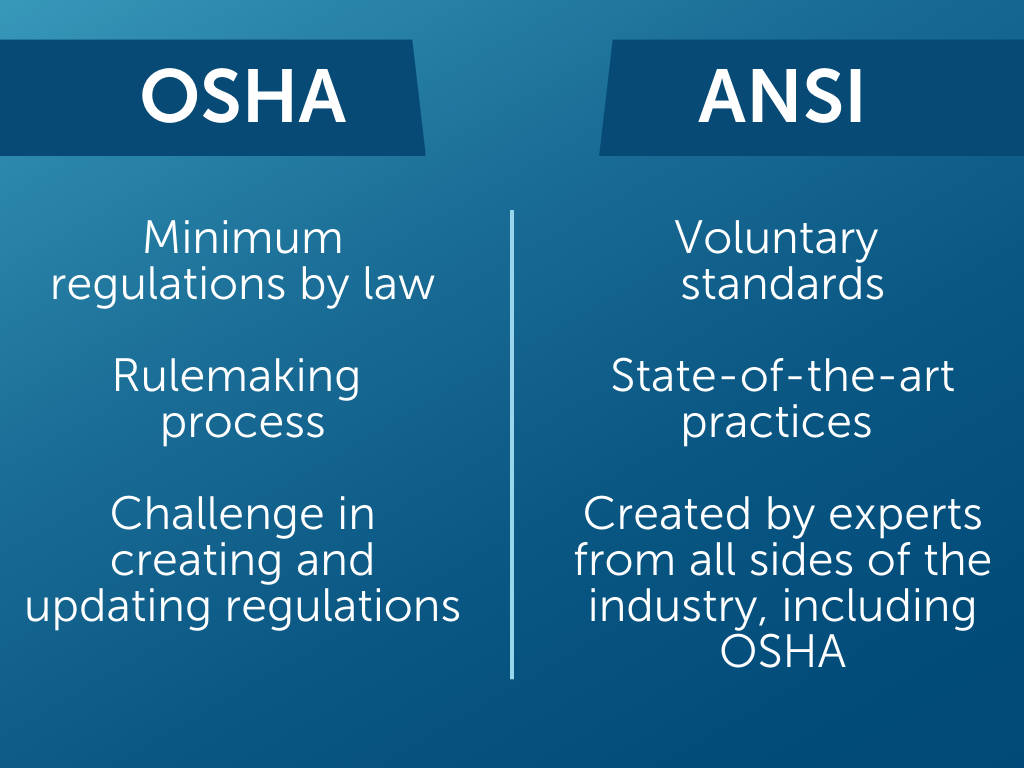

OSHA Regulations vs. ANSI Standards

With your goals and objectives in mind, you need to turn to a source of truth. In the United States, the Occupational Health and Safety Administration (OSHA) and the American National Standards Institute (ANSI) are two primary sources you can use for guidance. You should also check if your state has a state plan or uses the federal OSHA regulations.

OSHA provides the minimum regulations you need to adhere to by law and is driven by a rulemaking process. Since it’s a legislative process, there are challenges in creating and updating regulations. OSHA 1910.28 and OSHA 1926.501 state the duty to have fall protection and falling object protection (for general industry and construction respectively) provided by employers.

ANSI defines the voluntary standards that you should aim for to ensure you’re doing everything you can to protect your workers. They are state-of-the-art practices created by industry experts from all sides of the industry, including OSHA representatives. ANSI/ASSP Z359.2-2023 lays out minimum requirements for a comprehensive managed fall protection program.

Ideally, you would utilize your program goals and objectives to first ensure OSHA compliance with the ultimate goal of adhering to ANSI standards.

How to Build a Safety-Minded Culture

So, how do you build a culture focused on safety? It starts from within. Be honest with yourself. Are you doing everything you can to protect employees who work at heights? If you aren’t, take the opportunity to commit to protecting those who could be exposed to falls from that point forward.

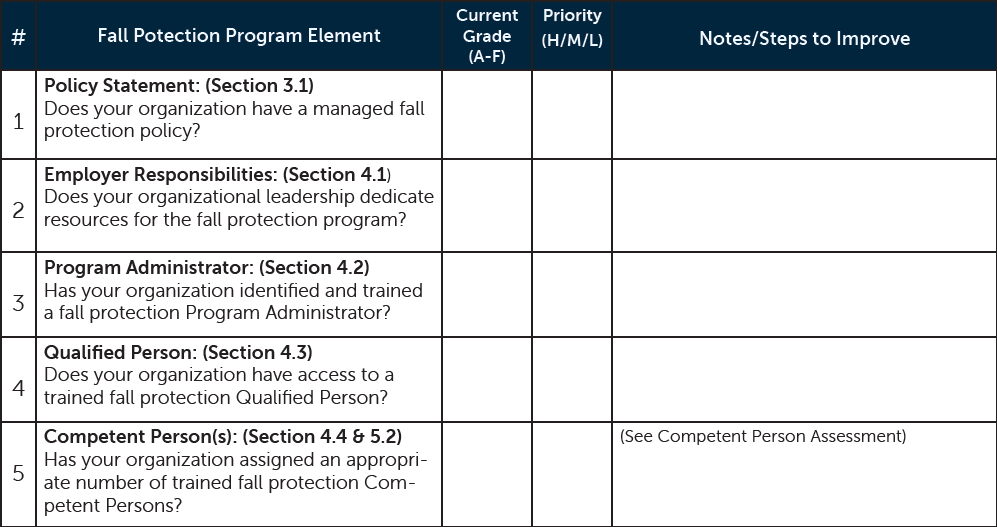

After you’ve asked yourself these questions, you can begin quantifying the current state of your fall protection program by performing a self-assessment. You can download a free Managed Fall Protection Program Assessment worksheet HERE. This assessment lays out various fall protection program elements based on ANSI Z359.2 standards. You can then give yourself a grade of A – F and designate a priority level of high, medium, or low, along with any relevant notes. This is a great way to think through and write out a plan of attack for the most important aspects of a fall protection program. You can build on this initial analysis by purchasing Z359 standards or taking the course ASSP offers on this.

Finally, you’ll want to gain buy in from everyone who will take part in the fall protection program—from those who implement it, including the people who use it for their work. Looping them into decision making and considering their input will increase their engagement. LJB fall protection expert, Kevin Wilcox, P.E., CSP, co-wrote an article titled, “Safety Gets Cultural,” on this topic. It’s a case study on how a Marathon refinery included employees in the development of its fall protection program and the positive outcomes they saw from it.

Here are some ways to get employees involved:

- Hold a safety day

- Create safety bulletins

- Start a suggestion program

- Involve them in the abatement process

- Explain why you want to prioritize fall protection

- Give employee recognition when a worker showcases desired safety practices

Building a culture focused on safety is how you’ll get it to stick. It says, “this is who we are and what we do” to your current and future employees.

Wrapping Up

There’s a lot to consider when you’re ramping up a fall protection program. Focusing on your goals and objectives, learning regulations and standards, and building a safety-minded culture are great places to start. You can download a fall protection program eBook HERE for a comprehensive overview of what it takes to build a program.

In future blogs, we’ll cover the components of a managed fall protection program. In the meantime, if you need expert help with your fall protection program, please feel free to reach out to us HERE.